How Premier Aluminum Llc can Save You Time, Stress, and Money.

How Premier Aluminum Llc can Save You Time, Stress, and Money.

Blog Article

The 6-Minute Rule for Premier Aluminum Llc

Table of ContentsThe Greatest Guide To Premier Aluminum LlcThe Ultimate Guide To Premier Aluminum LlcThe Definitive Guide for Premier Aluminum LlcA Biased View of Premier Aluminum Llc

(https://old.bitchute.com/channel/CkdxmIkh56Dq/)Making use of reduced price and unqualified suppliers can trigger quality problems, and lost time and cash in the long run. To help you with the procedure, right here are some points to consider when picking the ideal steel casting supplier.

A firm that only utilizes the investment spreading process will attempt to offer you on why that process is best for your application (Foundries in Wisconsin). What if utilizing the sand spreading procedure is best for you and your requirements? Instead, look for a provider that uses a range of casting procedures so the very best alternative for YOU is chosen

If functioning with a single source for every one of your casting requires is necessary to you, the supplier needs to be varied in its capabilities. When integrated with other incorporated abilities, this can aid simplify and press the supply base. When picking the right spreading vendor, mindful consideration must be provided to top quality, solution, and rate.

Not known Facts About Premier Aluminum Llc

Buyers progressively choose casting vendors that have machining capabilities. If the spreading supplier discovers a problem throughout machining, the issue is fixed faster with no disagreement over whose fault it is.

Problem or no, integrated machining simplifies the supply chain and minimizes dealing with time and delivery price prior to the product makes it to the client. What do you need from your spreading vendor? Are you seeking a person to simply supply a metal component to your doorstep or do you require a lot more? If you do not have internal metallurgy knowledge, confirm that the supplier can offer advice in picking the correct alloy based on your specific application.

Others will surpass the letter of the PO to help you conserve money and time. Do you have requirements for both ferrous and non-ferrous alloys? Some factories are minimal or specialized. See to it the supplier can meet all your material or alloy demands to remove the requirement for several vendors.

Premier Aluminum Llc Things To Know Before You Get This

Study the supplier's site. Talk to a sales associate or company associate.

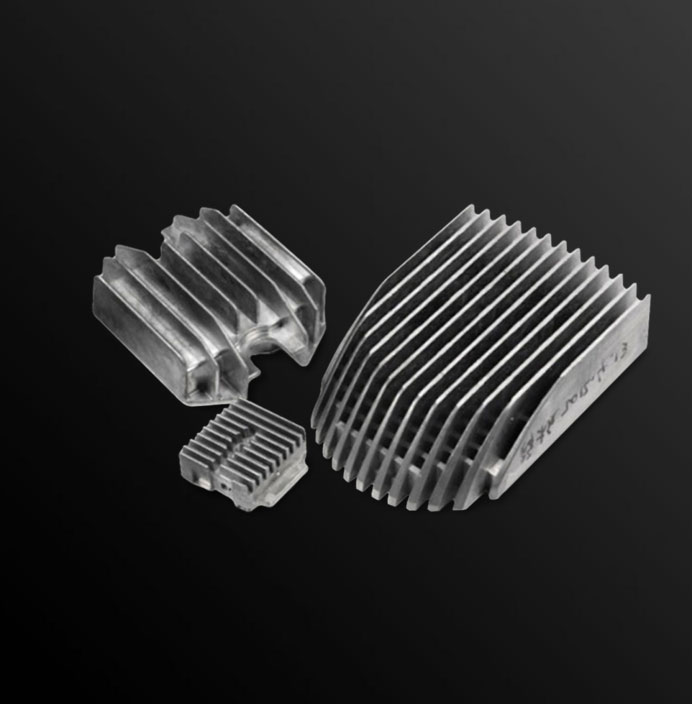

Aluminum is likewise light-weight and has good deterioration resistance, making it optimal for applications where weight and resilience are very important elements. In addition, aluminum casting is an economical technique of manufacturing, as it needs much less energy and resources than other techniques. Iron casting, on the other hand, includes pouring molten iron right into a mold and mildew to produce a desired shape.

The Best Strategy To Use For Premier Aluminum Llc

Iron casting is additionally able to hold up against high temperatures, making it ideal for usage in applications such as engine parts and industrial machinery. Iron casting can be much more pricey than light weight aluminum casting due to the higher price of raw materials and the energy required to thaw the iron. When choosing in between aluminum casting and iron casting, it is vital to take into consideration the specific demands of the application.

In final thought, both light weight aluminum casting and iron spreading have their very own special benefits and negative aspects. There are 3 sub-processes that fall under the category of die casting: gravity pass away spreading (or permanent mold casting), low-pressure die casting and high-pressure die casting. To get to the ended up product, there are 3 key alloys utilized as die spreading material to select from: zinc, aluminum and magnesium. Report this page